When it comes to making decisions and optimizing data use, it’s more important than ever to manage your company data as efficiently as possible. Especially when you’re transferring up to 2 terabytes of data per day. TIMETOACT is implementing an overarching data model in a data warehouse for TRUMPF Photonic Components, using Talend for data integration. Standardizing data management will provide TRUMPF with reports based on reliable data and enable the company to transfer the model to other technical departments.

- Non-standardized provision of information, different technical and professional know-how of employees, use of different data systems

- No higher-level data management in place, therefore no effective collection, storage and processing of company data

- Slowed data provision and decreasing trust in data

- Provision of a BigData and Analytics platform

- Standardization of processes and tools

- Modeling of a central analytical data model

- Implementation of the data model in a data warehouse (platform: MS SQLServer)

- Development of the necessary data integration (platform: Talend)

- Central provision of the information in a business intelligence frontend (technology: MS PowerBI)

- Platform is already productive for the logistics area and can be transferred to other departments

- Access to quality-assured, up-to-date information is possible at any time

- Independent creation of reports by TRUMPF

We are very satisfied with the result. Due to the very close cooperation, challenges could be critically scrutinized and the optimal solution could be found together - a win-win situation for both sides.

Thomas GöttlIT ManagerTRUMPF Photonic ComponentsA platform for big data and analytics required

Across the company, TRUMPF Photonic Components faced challenges such as the non-standardized provision of information, employees with different technical and specialized knowledge, plus the use of different data systems and technologies. It was impossible to gather, store or process data effectively, as the laser diode manufacturer did not have a platform for overarching data management. This affected up to 2 terabytes of data that was being transferred each day. It was not possible to ensure that the data was correct and traceable in the long term, and analytics queries sometimes put a great strain on the system. As a result, data provision was slow, and above all, trust in the data was dwindling.

TRUMPF’s key requirement was a big data and analytics platform that would allow the company to manage data effectively.

‘We want to use the new platform to standardize our tools and processes, so we can manage our huge data load effectively and create meaningful reports,’ said Thomas Göttl, Head of IT at TRUMPF Photonic Components.

The platform needed to meet specific requirements across departments while allowing integration into the technical system environment. The goal was to be able to work, plan and make predictions analytically based on reliable data and avoid relying on the knowledge of individual employees.

We had known the TIMETOACT experts for some time. Their mix of analytics skills and Talend expertise made them ideal partners.

Thomas GöttlIT ManagerTRUMPF Photonic ComponentsMultiple partial solutions working together

TIMETOACT came on board in autumn 2020 to implement a big data and analytics platform and provide consulting on Talend. The overall project consisted of multiple partial solutions that built on each other.

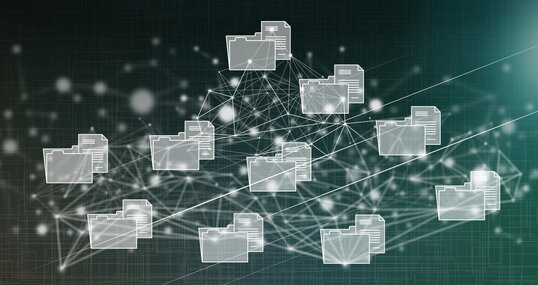

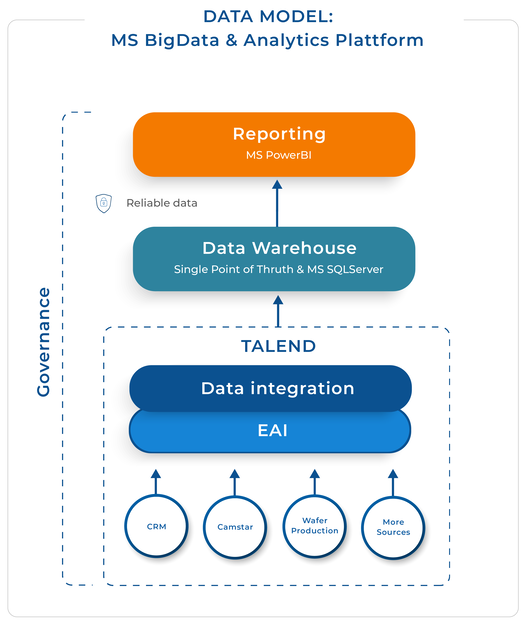

Visualization of the implemented data model

1. Modelling a central analytical data model

To set the project up for success, we began with detailed workshops for all TRUMPF stakeholders to collect all the requirements for the analytics platform. TIMETOACT analytics architects then defined and developed a suitable data model based on those requirements.

2. Implementing the data model in a data warehouse (platform: MS SQL server)

In the introductory and design phases, we talked about using a data lake to realize the data model, but following new insights from the workshop, we decided to change the requirement to a data warehouse. The reason was that, from a technical perspective, we wouldn’t need to collect real-time or unstructured data. Traditional layer modelling in the data warehouse provides a central and transparent single point of truth, which can be queried by the usual BI tools and therefore integrated into the TRUMPF system environment. The data warehouse is also scalable and can be used to meet many other requirements in the future.

Example of reporting in MS Power BI based on the data model

3. Developing the necessary data integration processes (platform: Talend)

After mapping the data model in the data warehouse, we began developing data integration processes using Talend. The platform enables you to automate the provision of data from various sources to the data warehouse in a manner that is functionally and technically compatible. That way the data is always transparent and accessible and does not depend on people or feeder systems being available. At the same time we trained TRUMPF staff in using Talend to manage the data model.

4. Providing information centrally in a Business Intelligence frontend (technology: MS Power BI)

TRUMPF’s data management team makes the reports available in Power BI. The reports are based solely on reliable data from the data warehouse and can be used to query production status, for instance.

TIMETOACT creates a data foundation for additional processes

The whole project ran remotely due to the pandemic and was completed in autumn 2021. The platform is now live for the Logistics division and is planned to be rolled out for additional departments. Data integration processes run regularly, and end users receive information. This specialist, technical platform allows them to access top-quality, up-to-date information required for making good business decisions at any time.

TRUMPF’s clear requirements, plus the distinct roles and distribution of tasks on both sides were a key advantage when it came to executing the project. TIMETOACT experts supported the project all the way through, from gathering requirements to creating the data warehouse and integrating the data – supervised by the architects who held the initial workshops. In the future, TRUMPF will be able to continue developing the processes and transfer them to other technical departments themselves thanks to the expertise they’ve gained from TIMETOACT.

Data hub with GROUP support

They have already extended the data model and data integration process to include sales data and are working on implementing data governance (data documentation) for the data model. TIMETOACT’s analytics experts continue to be involved as partners and consultants for new projects, such as the implementation of a data governance solution in other technical departments or a data science platform that’s planned for the future.

A project to implement real-time integration of the feeder systems is currently underway: X-INTEGRATE, who are TIMETOACT GROUP’s experts in areas such as process integration, EAI and data hubs, are helping TRUMPF add real-time components to the existing Talend platform. They are creating a data hub between the operative systems which will allow them to communicate via REST API.

The analytics platform created as a result of this collaboration will also support the development and production of quantum computer chips.

Thomas GöttlHead of ITTRUMPF Photonic ComponentsThe TRUMPF Group recently reported an investment of several million euros in this technology.